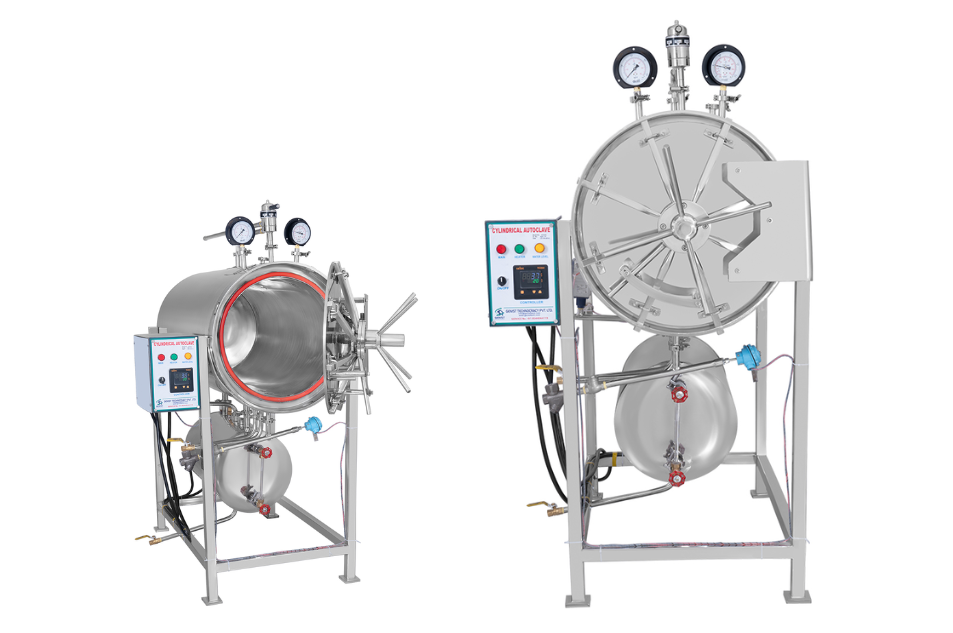

When it comes to the sterilization aspects, horizontal cylindrical autoclaves are the best for big-volume applications. These powerful steam-generators are used for disinfection of laboratory equipment, medical instruments, and industrial materials and they do this by using pressurized steam which kills microorganisms to ensure sterility.

Here comes the vital role of autoclave sterilizer manufacturers in meeting these needs.

Let us take you through the world of horizontal cylindrical autoclave sterilizer manufacturers and understand their functions, capabilities, and how to choose the right supplier.

Understanding Horizontal Cylindrical Autoclave Sterilizers

The horizontal cylindrical autoclaves are pressure-resistant chambers that disinfect materials using high-pressure steam sterilization. They are circular housing units placed horizontally for easy loading and unloading from both sides. These autoclaves are furnished with heating elements for vapor and pressure control to ensure the desired sterilization.

The main use of the horizontal circular autoclave is to sterilize equipment and materials by placing them in hot water. It is also used to decontaminate laboratory waste, medical waste, and other hazardous materials. During the autoclave process, extremely high steam is used to kill all the bacteria, which makes the waste suitable for safe disposal.

The Role of Autoclave Manufacturers

The manufacturers of horizontal cylindrical autoclave sterilizers are the key players in fulfilling the extensive list of sterilization necessities of the healthcare industry, pharmaceutical companies, science and technology research, and manufacturing. These producers develop, design, and build autoclaves that meet stringent quality standards and regulatory requirements to achieve safe and effective sterilization and customer safety.

Capabilities and Offerings

Product Range: Manufacturers have successfully provided various horizontal cylindrical autoclaves with different capacities, sizes, and features that are suitable for multiple applications and customer specifications. It could be the benchtop units for research labs, mid-size units for small-scale production, or large-scale systems for industrial purposes.

Customization: Many producers can also add to the autoclave customization features that will suit individual customers’ needs. Such changes may consist of dimension reduction, material change, control adjustment, and the addition of complementary features to fulfill a specific sterilization task or to be used in facilities with certain restrictions.

Technology and Innovation: Leading manufacturers spend funds on research and development and implement advanced technologies and innovative traits into their autoclave solutions. These innovations include user-friendly touch screens, programmable sterilization mode, remote monitoring ability, and energy-efficient designs.

Compliance and Certification: Autoclave sterilizer manufacturing is built in compliance with industry standards and regulations, including ISO, FDA, CE, and ASME. Certifications and compliance are important for showing that the autoclave systems are reliable, efficient, and secure. The customer and the regulatory authority will be more confident as a result.

After-Sales Support: Besides autoclaves, they also offer aftersales services as a package deal, which include installation, training, maintenance, calibration, and technical assistance. Customer complaints about the autoclave systems may be avoided by providing dependable post-sale support, ensuring optimal performance, longevity, and user satisfaction with these systems.

A Landscape of Expertise

Customized Medical Devices: These horizontal cylindrical autoclave sterilizer manufacturers typically have a good reputation in the medical field and provide specially designed autoclaves for healthcare facilities. Their models prioritize specific features such as user-friendliness, medical compliance, and integration into the existing clinical system.

Supply of Scientific Equipment: These manufacturers mainly serve laboratories and universities. Their autoclaves can emphasize features such as advanced control systems, data logging capabilities, and compatibility covering a wide range of laboratory equipment.

Industrial Sterilization Specialists: These manufacturers concentrate on industrial applications like food preparation and pharmaceuticals, and their autoclaves can have high-volume penetration and integration within the manufacturing processes. Their models consider factors like fast cycle times, extensive room sizes, and high levels of automation.

Assessing Your Needs

Chamber with Enough Room: Consider the size of the biggest container you need to sterilize. Manufacturers offer a range of sizes, from medium-sized models suitable for research labs to larger structures capable of meeting the needs of industrial applications.

Required Features: Autoclaves with modern advanced features are expensive· Therefore, you should go through your sterilization needs before making a final decision· Are special smoothing techniques necessary? Do you need to track each sterilization cycle? Just choose the features you will use.

Safety Certifications: Verify that the autoclave meets applicable safety standards such as the American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code· Priority will be given to manufacturers committed to safety and quality.

Customer Service: Reliable after-sales support is essential to maintaining your autoclave. Look for manufacturers known for fast turnaround times, readily available spare parts, and qualified professionals.

Conclusion

Horizontal cylindrical autoclave sterilizer manufacturers play a critical role in providing sterilization solutions to industries across the globe that have diverse needs· By knowing what they can do, what they offer, and what should be considered when selecting them, stakeholders can base their choice of manufacturer for their sterilization needs on objective knowledge·

Whether the sterilization process is for compliance purposes, performance optimization, or efficiency enhancement, selecting the right manufacturer is vital in attaining high-quality sterilization results.